Jet Heat & Micro Jet

Flameless Heaters

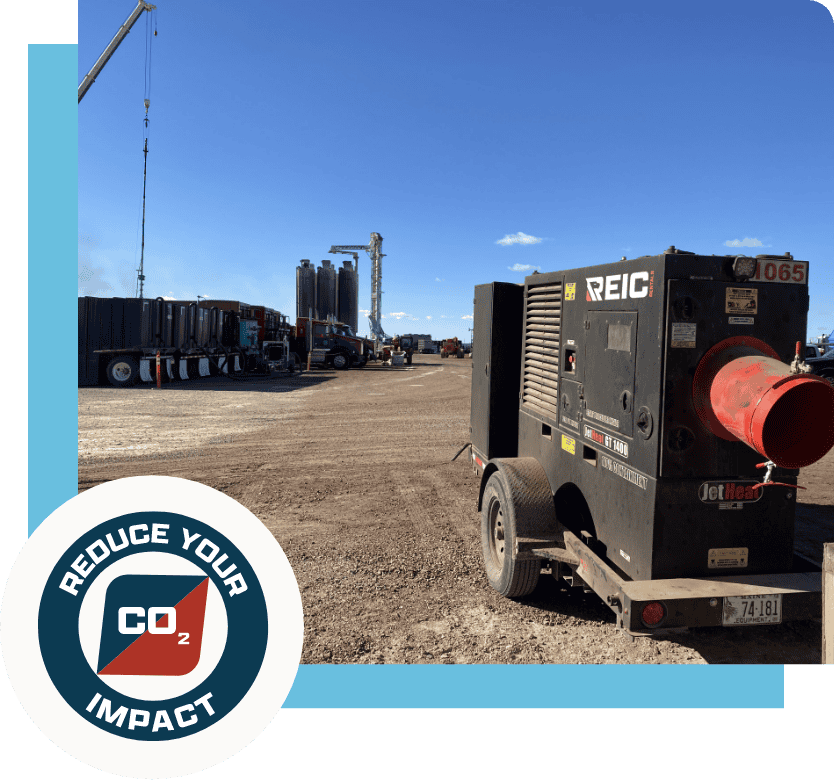

Exclusive, patented heating technology you can only rent from REIC Rentals

Jet Heat and Micro Jet are not standard rental heaters. They are exclusive to REIC Rentals, powered by patented jet-engine technology that we own and deploy across North America. When your project depends on safe, reliable heat in extreme conditions, these flameless heaters deliver the performance and efficiency that traditional heaters cannot match.

Jet Heat & Micro Jet

Flameless Heaters

Exclusive, patented heating technology you can only rent from REIC Rentals

Jet Heat and Micro Jet are not standard rental heaters. They are exclusive to REIC Rentals, powered by patented jet-engine technology that we own and deploy across North America. When your project depends on safe, reliable heat in extreme conditions, these flameless platforms deliver the performance and efficiency that traditional heaters cannot match.

Why Jet Heat is different

Most temporary heating challenges are not solved by “more heaters.” They are solved by better heat delivery.

Jet Heat and Micro Jet are designed to:

- Deliver heated air further through ducting, with the pressure to reach deep into large buildings and work zones

- Reduce heater count by replacing multiple conventional units with fewer high performance heaters

- Cut refuelling frequency and simplify site logistics with lower fuel consumption

- Provide clean, breathable, flameless heat that supports safer working conditions in enclosed and semi-enclosed environments

- Run as a self-contained system with no external power required, ideal for remote site and fast mobilizations

Jet Heat

Highlights:

- Hot air delivery up to 500 feet with ducting for deep coverage

- Fuel consumption range designed to match the demand of the job

- High static pressure that can support long runs and multi-feed layouts

- Variable output settings to right-size heat to the conditions

- Rugged, job-built design for tough environments

- Self-contained, no external power required

- Clean, breathable air output

- Secondary containment and jobsite-ready safety features

- Onboard diagnostics with safety shutdown capability

1.4M

BTU EQUIVALENT

up to

95%

Reduced Fuel Cost

500'

Heat Distribution

Micro Jet

Highlights:

- Hot air delivery up to 350 feet with ducting for targeted coverage

- Extremely fuel-efficient operation for long runs and remote work

- High static pressure for ducting, enclosures, and directed heat delivery

- Compact footprint with big jobsite impact

- Self-contained, no external power required

- Clean, breathable air output

- Secondary containment and jobsite-ready safety features

- Onboard diagnostics with safety shutdown capability

as low as

2.9GPH

Fuel consumption as low as

97%

Engine Efficiency

4

Indirect Heaters Replaced

Fewer heaters.

Less Labour.

Cleaner Sites.

Jet Heat is built to reduce the hidden costs of temporary heat

Less equipment clutter

Fewer heaters to place, protect, and manage

Simpler ducting plans

Long-throw capability means fewer setups and fewer “dead zones”

Reduced refueling runs

Lower fuel consumption reduces site traffic and spill risk

Less downtime

Technology designed for consistent performance with monitoring and diagnostics

Safer working conditions

Flameless heat and clean output support healthier jobsite environments

Lower total heating cost

Fewer units, less labor, less handling, and more effective coverage

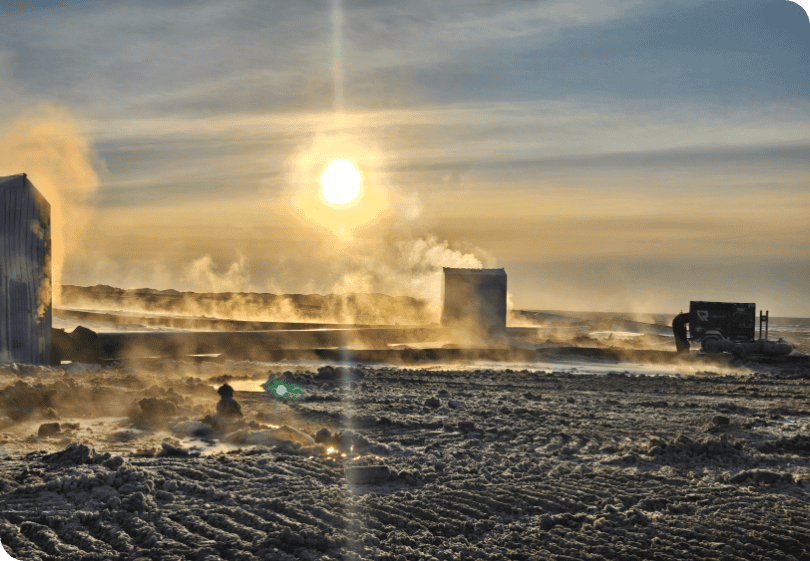

Field-proven on major projects

Jet Heat is not “theory heat.” It has been deployed on some of the most demanding job sites:

Multi-million square foot winter construction

A Midwest construction team scaled to a large fleet of Jet Heaters to heat a building spanning more than 3 million square feet, pushing heat deep into the interior through long duct runs and maintaining target temperatures through severe cold snaps.

High-rise concrete work in dense urban environments

A concrete contractor replaced labor-intensive heating methods with a single Jet Heater that could be moved floor-to-floor, reduced cleanup burden, improved working conditions, and eliminated the need for continuous fire watch associated with open-flame approaches.

Oil and gas production and workover sites

A production operator moved from testing a single unit to deploying Jet Heaters across multiple sites, using one heater per location and splitting outlets to heat both equipment and personnel zones. The result was fewer heaters required on each pad and meaningful fuel and logistics savings.

Cleaner performance and ESG-ready advantages

Major project teams increasingly need heat that supports both budget and sustainability goals. Jet Heat and Micro Jet are built for that reality:

- High-efficiency operation designed to reduce fuel consumption versus traditional approaches

- Lower emissions profile compared to many conventional jobsite heating methods

- Reduced refueling frequency that cuts traffic, labor, and spill risk

- Equipment tracking and monitoring capabilities that support fleet control and reporting

- A practical path to documenting job decisions with fuel and runtime visibility for internal reporting and ESG conversations

Common applications

Jet Heat and Micro Jet are used across construction and industrial environments where reliable, directed heat is essential:

Construction

- Concrete curing and winter pours

- Ground thaw and cold-weather earthwork support

- Multi-storey and high-rise heating plans

- Shotcrete and enclosure heating

- Worker comfort and productivity in cold climates

Oil & gas

- Drill deck and pad heating

- Pump station and waterline heating

- Frost prevention strategies

- Wellhead and BOP heating support

- Pipeline thermal conditioning and pre-expansion support

Coatings & surface work

- Tank coating and cure support

- Temperature stability for coating windows

- Humidity management support when paired with drying and airflow solutions

Construction

- Concrete curing and winter pours

- Ground thaw and cold-weather earthwork support

- Multi-storey and high-rise heating plans

- Shotcrete and enclosure heating

- Worker comfort and productivity in cold climates

Oil & gas

- Drill deck and pad heating

- Pump station and waterline heating

- Frost prevention strategies

- Wellhead and BOP heating support

- Pipeline thermal conditioning and pre-expansion support

Coatings & surface work

- Tank coating and cure support

- Surface prep and de-icing

- Temperature stability for coating windows

- Humidity management support when paired with drying and airflow solutions

More than heaters:

complete cold-weather execution from REIC Rentals

Jet Heat and Micro Jet perform best when the full plan is engineered. REIC Rentals supports the entire deployment, including:

- Heat planning and equipment right-sizing based on zones, ducting routes, and phasing

- Ducting strategy for long runs, multiple feeds, and targeted delivery

- Delivery, setup, startup, and on-site support options for critical schedules

- Integrated packages that combine heating with what the site actually needs:

- Temporary power and lighting for winter operations and night work

- Pumps and water management for snowmelt, runoff, and freeze-thaw cycles

- Ventilation and air movement for enclosures and controlled work zones

- Dehumidification and drying when moisture control is part of the scope

Frequently asked questions

Still have questions?

If you need additional information or clarification, please contact our team and we’ll be happy to assist.

What makes Jet Heat and Micro Jet different from standard rental heaters?

Can one heater serve multiple areas?

Yes. Many projects use ducting strategies and multi-feed layouts to direct heated air to multiple zones from a single heater placement, depending on layout and ducting design.

Do these heaters work for major buildings and deep interior zones?

Are these heaters suited for remote or utility-limited sites?

Can REIC Rentals provide on-site support?

Can these heaters support cost and ESG reporting goals?

Still have questions?

If you need additional information or clarification, please contact our team and we’ll be happy to assist.

Put Jet Heat on your project plan

Tell us your location, work zones, timeline, and constraints. We will build a heating plan using Jet Heat and Micro Jet that reduces heater count, improves coverage, and supports safer, more productive winter work.